The products I work on are mostly monoclonal antibodies (and the occasional gene therapy product mixed in). So, the types of diseases they are used to treat vary. To be honest, I work on the process/formulation side of the development pipleline and the actual clinical treatment part is pretty much inconsequential to what I do. Some of the past programs I have worked on include treatments for asthma, eczema, multiple myeloma, breast cancer, MS, hemophilia, and tons of others that I don’t remember. Often, when dealing with antibodies, the same medicine can be effective for multiple indications.

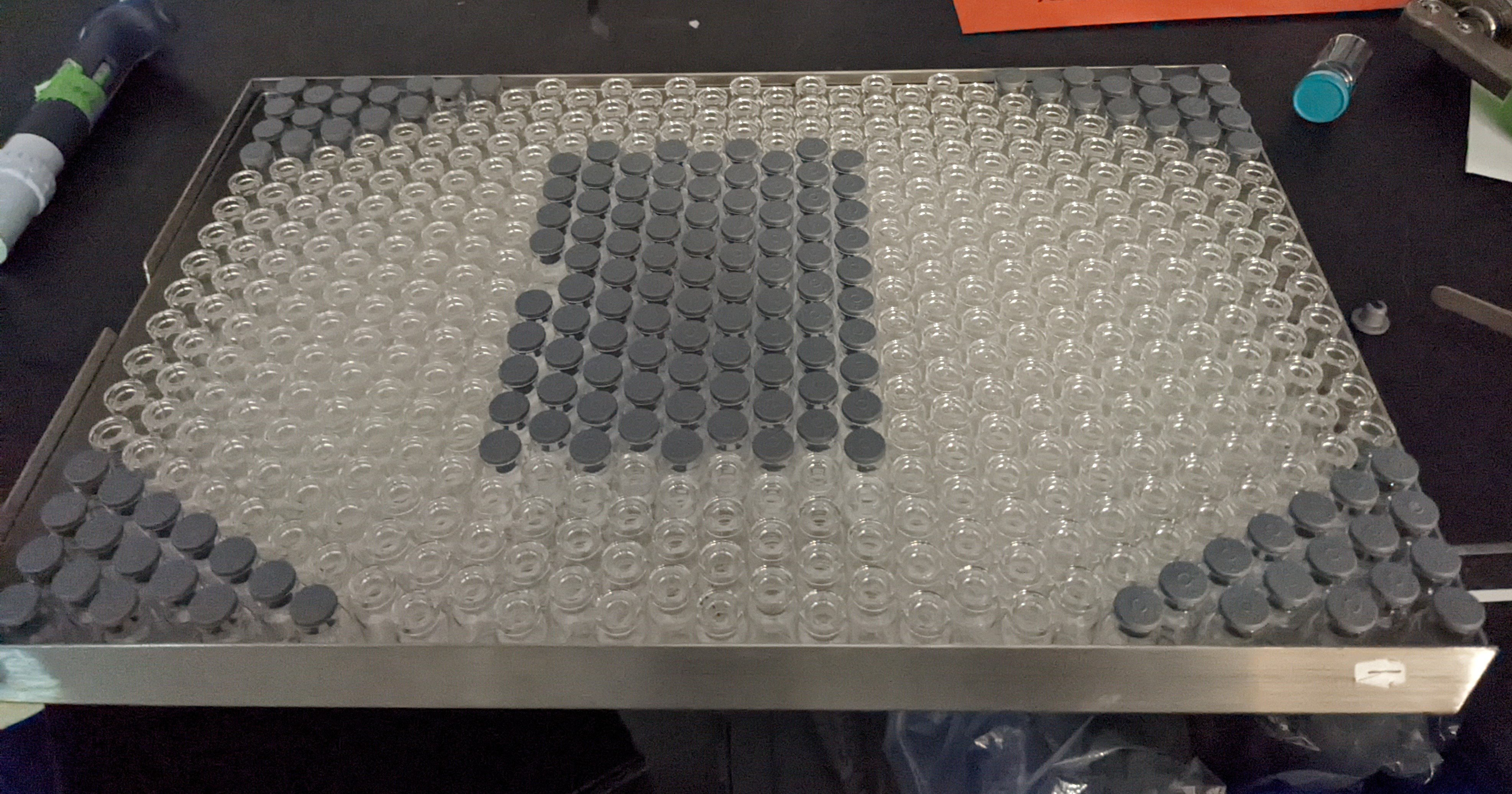

The finished vials, post-lyophilization, sealing, labeling, and packaging, are sent to infusion clinics. There, clinicians will add water to the vials to reconstitute the drugs and then administer them to patients via IV (usually).

I work in pharma, regularly writing and filing things with the FDA (and other agencies), and this has been a topic of conversation at work. The good news for people is that the EMA is still a thing in the EU. So, at least the large pharma companies (like the one I work for), are likely to not really change much about their quality control/processes/etc. because we will still need to conform to the EMA guidelines which are typically in line with the current FDA (sometimes more strict, sometimes less so). The real quality concern would be smaller companies that only file for products in the US. They would only need to meet whatever new FDA guidelines come into effect (if they even do, changing stuff like GMP guidance is extremely complicated and time consuming) since the US is their only market.